Our product portfolio has grown significantly over the past 20 years, and has been the foundation of our success. In order for this to be maintained in the future, the company has decided to develop new products based on cutting-edge technologies and innovative production methods.

The commitment of Georgiadis S.A. for top quality products is our top priority and that is why we invest in modernization, improvement of production sites and Quality Control. We use highly automated production processes while applying technological certifications in accordance with European standards.

Over the last ten years, in our effort to provide our partners with technical support, we have gained experience and high know-how through the study and testing of base materials and finishing techniques. The results of our R&D department enable us to respond quickly and efficiently on our individual customer needs.

Working with major European companies in the industry and participating in their workshops has provided us with valuable support and knowledge.

QualiTronic Color Control

With QualiTronic Color Control technology, ink density measurement and control is implemented directly at the press systems. A camera-mounted console is installed after the last printing or coating unit and allows the optical density to be automatically measured on the printed colour bars. These measurement values serve as the basis for fast dynamic inline control of the ink key settings.

System Brunner’s INSTRUMENT FLIGHT®

With System Brunner’s INSTRUMENT FLIGHT®, not only individual colours (standard solid density measurement) are measured, but also direct 3D overlay in mid-shades and shades (colour balance). Ink controls are based on these priority parameters, ensuring that the visual result complies with colour specifications.

MGI JET varnish 3D Evo

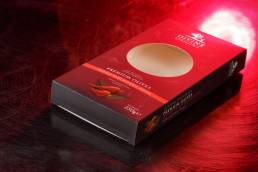

The need for a different approach to the customer, in order to meet his/her specific needs and respond to new market demands – small printing, on demand production, cost reduction, better quality output – has led us to choose a high productivity and performance digital solution.

The MGI JET Varnish 3D Evo, thanks to its B1 + shape, its industrial platform with pallet feed and extraction system and state-of-the-art AIS technology, is ideally suited for setting up such a production.

The real breakthrough is the AIS Smart Scanner © system, Touchless Sheet Registration technology, that scans and analyses every individual sheet fed through the system and then adjusts and modifies inkjet head performance in realtime to compensate and correct for any printed or physical imperfections on the sheet.

By using embossed varnish and foil metallic textures in variable data (VDP, VDF), the corporate communication is personalized in such a way that people can see, feel and remember the brand.

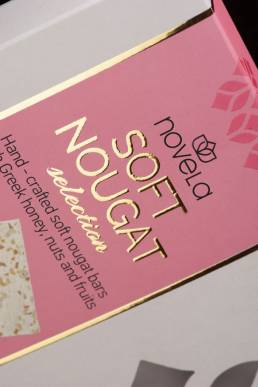

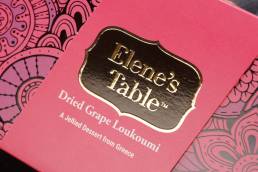

Color Logic

Our constant investment in the end result of our finished products has led us to cooperate with Color Logic, a leader in metallic colour communications systems for decorative and stochastic colour prints.

Its flagship product, Process Metallic Color SystemTM software, enables colour printing systems to deliver metallic colours.

Ricoh Pro C7100 Series Systems

We improve the end result with the Ricoh Pro C7100 Series 5 colour stations Systems, the only one worldwide that can print on metallic and reflective surfaces using white ink, in addition to CMYK inks.

- Faster response to market needs - products and various marketing aids are produced without trial and error.

- Simulate 250 new metallic colours and shades using only 5 colours, CMYK and white. Easy selection from the corresponding colour palette, as well as using special applications based on light reflection.

- High performance colour system even on thin surfaces.

- Creating printing effects based on foil.

- Printing special effects such as 3D, holograms, etc.

- Use of 5 colours (with white TONER) without additional equipment overlay.

- Immediate application without additional processing.

- Application of Metal colour simulation on the screen of the computer during design.

KBA RAPIDA 106

Maximum production capacity with fully controlled end result through the use of KBA RAPIDA 106 machines

The world’s largest printer maker, Koening & Bauer AG (KBA), is lighting a real innovation firework with world-class champion Rapida 106.

- Varnish unit with automated replacement of Anilox cylinder with AniloxLoader.

- Optimized AirTronic export for a specific volume of paper at even higher speed.

- Updated quality control system.

- Ergo-Tronic control console with large screen, similar to those found in large printing machines.